CHOOSING THE RIGHT TAIL SWING

Understand Zero, Minimal, and Conventional Tail Designs

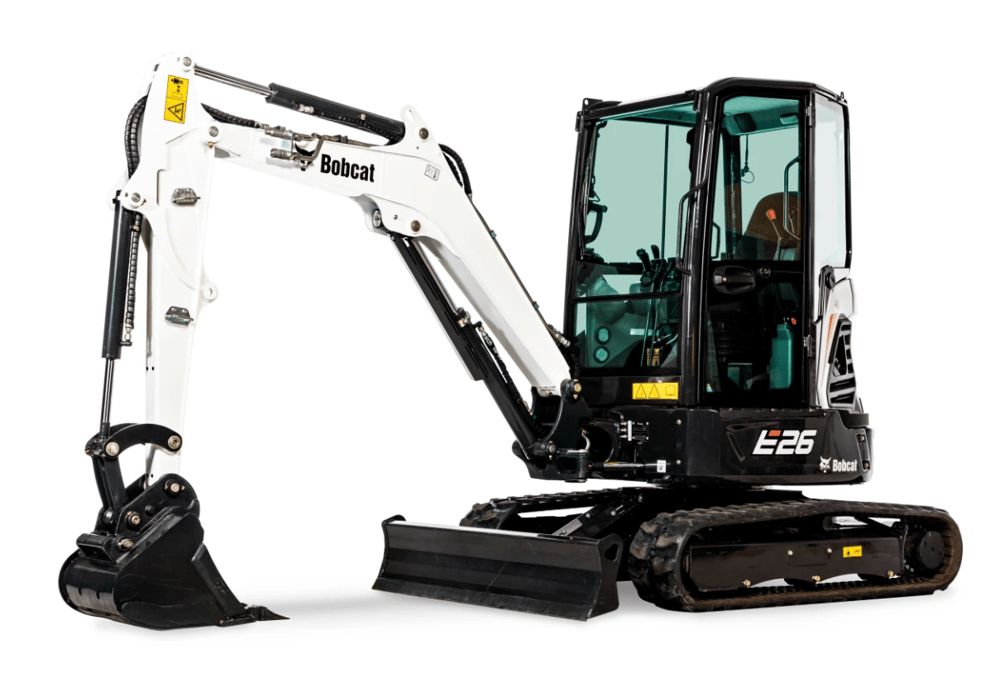

ZERO TAIL SWING

Zero tail swing excavators are built for tight spots and tough angles. The counterweight stays inside the track width as the machine rotates—so there’s no overhang to worry about. That means fewer collisions, less downtime, and more confidence working close to walls, foundations, or obstacles. The Bobcat E35 with a standard arm is a prime example—tough, compact, and made for the grind in crowded job sites.

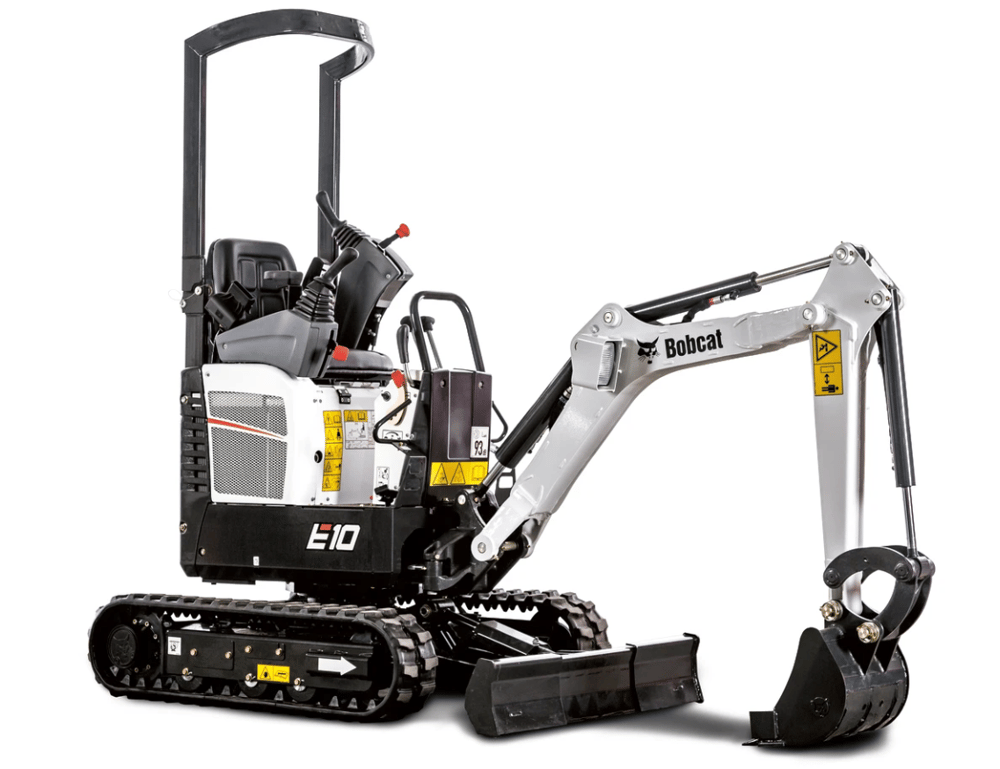

MINIMAL TAIL SWING

Minimal tail swing excavators strike a solid middle ground—offering more lift and balance than zero tail, without going full-sized. The counterweight extends just a bit past the tracks—like the Bobcat E26, which swings out only 1 to 1.5 inches—giving you added muscle while still fitting into tighter job sites. It's built for operators who need power and precision without the bulk.

CONVENTIONAL TAIL SWING

The conventional tail swing is the workhorse of excavators—built for power and performance. Its counterweight sticks out well beyond the tracks, demanding extra room to swing but delivering serious digging strength and stability. Machines like the Bobcat E32, a true conventional tail model, swing out about 16 to 17 inches past the tracks, making them perfect for wide-open job sites where muscle matters more than maneuverability.